This critter is a speedometer from a 1990 Porsche 964. I call these "hybrid" speedos because while they are ELECTRIC [not cable driven], they still retain the mechanical

odometer registers.

The usual problem with these speedos is the break-up of a couple of wee little odometer drive gears that were shit quality to begin with. Of course, you have to

take these things all apart to get to those little gears. On the left, above, is the

speedometer assembly, with its printed circuit board. In the middle, a plastic gasket, and on the right, the outer, steel, "can" or housing. The outer rings and the [plastic]

glass have already been removed. [Uhhh...PLASTIC glass? In a Porsche? Oh my...]

Here the printed circuit board has been separated from the main frame of the speedometer. We still are no where near the busted-up wee gears, but we're

gaining on it...

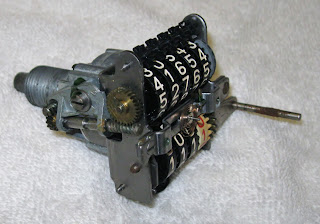

Believe it or not, this mish-mash is a little pancake motor that drives just the speed needle. It is fed by a little sensor somewhere in the bowels of the car, driven off the

final drive of the transmission. And...of course, there is another little motor that drives the odometer gears. And, assuming you can find THAT motor, you'll find the little busted drive gears jammed in behind it. Keep looking...

See, when the crappy little gears shredded, they sent little gear bits all through the

rest of the speedo. You have to take the bloody speedo all apart--usually--in order

to use dentist's torture tools to dig out all the little gear parts. If you don't, those

broken up parts will sure as hell screw up the new gears you install. Fun stuff....

Here is the reconditioned, CLEANED-UP, speedometer, WITH new wee gears. The

new gears are made of a different, high quality material that will probably outlast

the rest of the speedo. They will certainly outlast the [plastic] "glass"........HA!

Friday, September 30, 2016

Monday, July 25, 2016

SAAB ALTERNATOR RECONDITIONING

Let's ALTERNATE! The photo above shows before and after my reconditioning work.

Though you can't tell unless you look very carefully, it also shows that one alternator

is for a two stroke Saab and one is for a V4, though both have the early cast aluminum fan.

Now look at the FINS on each fan from the back. Note that the fins angle in opposite directions. While both engines turn the same direction [clockwise as viewed from the front], remember that the V4 fan pulley is on the BALANCE SHAFT, so the alternator turns the opposite direction. It is also good to remember that an alternator doesn't give a shit which way it turns---it just produces alternating current [AC]. The "juice"

is then fed through a full wave rectifier whose output is direct current [DC], the stuff the car needs. Cool, huh?

This photo shows all the gubbins. Note that I turned the commutator slip rings on the armature [brass color] down smooth on my lathe. The brush pack is on the extreme left. This alternator is a later unit [tho all are 35 amp, 12 volt] that used the stamped steel fan with the fins angled the correct direction for the Ford/Saab V4.

Here are three alternators that I just reconditioned. Left--late V4. Center--V4, sort of early, with aluminum fan. Note the arrow on the fan, indicating direction of rotation. The alternator on the right is a VERY early V4, also with a cast aluminum fan. So what is the difference between the one in the center and the one on the right?

The difference is in the electrical connections on the back. The one on the left and the one in the center use the 3-connector plug, plus a heavier B+ wire, plus a ground wire. The alternator on the right uses four separate connections, plus ground. All were used on Saabs, in various years, and all are 35 amp, 12 volt alternators.

I actually reconditioned six of the buggers, this session, but these three show the main differences that you might encounter. The most IMPORTANT thing to remember is that an alternator must have the correct fan. The arrow--either cast into the aluminum fan face, or stamped into several of the fins on a stamped steel fan--must indicate a counter-clockwise rotation for a V4. A cast aluminum fan for a two cycle Saab will have the cast-in arrow showing a clockwise rotation. Don't mix 'em up or you'll get to replace a burned-up alternator, and that's no fun...huh?

Though you can't tell unless you look very carefully, it also shows that one alternator

is for a two stroke Saab and one is for a V4, though both have the early cast aluminum fan.

Now look at the FINS on each fan from the back. Note that the fins angle in opposite directions. While both engines turn the same direction [clockwise as viewed from the front], remember that the V4 fan pulley is on the BALANCE SHAFT, so the alternator turns the opposite direction. It is also good to remember that an alternator doesn't give a shit which way it turns---it just produces alternating current [AC]. The "juice"

is then fed through a full wave rectifier whose output is direct current [DC], the stuff the car needs. Cool, huh?

This photo shows all the gubbins. Note that I turned the commutator slip rings on the armature [brass color] down smooth on my lathe. The brush pack is on the extreme left. This alternator is a later unit [tho all are 35 amp, 12 volt] that used the stamped steel fan with the fins angled the correct direction for the Ford/Saab V4.

Here are three alternators that I just reconditioned. Left--late V4. Center--V4, sort of early, with aluminum fan. Note the arrow on the fan, indicating direction of rotation. The alternator on the right is a VERY early V4, also with a cast aluminum fan. So what is the difference between the one in the center and the one on the right?

The difference is in the electrical connections on the back. The one on the left and the one in the center use the 3-connector plug, plus a heavier B+ wire, plus a ground wire. The alternator on the right uses four separate connections, plus ground. All were used on Saabs, in various years, and all are 35 amp, 12 volt alternators.

I actually reconditioned six of the buggers, this session, but these three show the main differences that you might encounter. The most IMPORTANT thing to remember is that an alternator must have the correct fan. The arrow--either cast into the aluminum fan face, or stamped into several of the fins on a stamped steel fan--must indicate a counter-clockwise rotation for a V4. A cast aluminum fan for a two cycle Saab will have the cast-in arrow showing a clockwise rotation. Don't mix 'em up or you'll get to replace a burned-up alternator, and that's no fun...huh?

Sunday, June 26, 2016

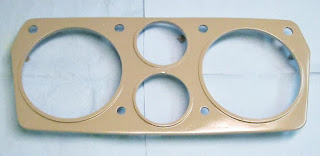

SAAB MONTE CARLO INSTRUMENT PANEL FOR STANDARD 95/96 CARS

Most Saab 95 and 96 owners want this instrument cluster in their instrument panel. I include myself in that group of Saab Nuts.... This is the reconditioned instrument set and reconditioned Monte Carlo instrument mount PANEL [see my blog, dated 5 May 16 for that drill...].

This is a dramatically cleaned up--but not sanded, primed and repainted--standard 95/96 instrument panel. Note that is is for a PRE- 1968 model, because it has the mount area for the inside rear view mirror at the top center of the panel. Remember-- the Saab 95/96 cars up to and including 1967 had SHORTER windshields and rear windows....

Here is a closer look at the area where the Monte Carlo instrument mount panel will be fitted. Note the rust and discoloration on the main panel. I had not yet cleaned it up, nor repainted it.

YIKES! A giant HOLE has to be cut to fit the MC panel in place. This has to be done VERY carefully because enough material has to be cut away to clear the instruments, but material must be left for the six mounting studs on the MC panel. I have done this modification before, so I have a pattern that takes the guess work out of the job.

MUCH very careful trimming must be done to get a good fit of the MC panel. The six warning light holders have to fit onto the back of the MC panel, which usually requires MORE very careful trimming. Finally, the edges of the stock Saab instrument panel--at the cut-out area--have to be bent to just fit evenly to the MC panel. That MC panel is made of 50 year old plastic, remember, and does NOT care to bend.

Saab glove box doors have seven main pieces, as shown. I disassembled the door, then sanded, primed and painted the four main parts. It was a lot of screwing around, just to get a good looking glove box door, in the correct color. But there it is....

This photo shows the flip side of the door. The cup holder part is on the left, the not yet installed Monte Carlo 850 panel on the table, in front...

...and here is the glove box door, reassembled, ready to install in the instrument panel. Looks good, eh?

OK...Here is the finished product....Cleaned, straightened, sanded, primed, sanded, primed, sanded, primed, then finally given 3 coats of color. Mighty nice, don't you think?

A closer look at the installed Monte Carlo instrument mount panel, fitted in place, with all the instruments and warning lights.

The final, finishing touch will be a new instrument panel TOP. There are no originals, period. There a VERY few factory replacement top panels around [which were made without the grooves] but good luck finding them. Mark Ashcraft builds an exceptionally nice fiberglass replacement top panel, which comes primed and ready for finish painting and installation. He includes very good How-To instructions.

This is a dramatically cleaned up--but not sanded, primed and repainted--standard 95/96 instrument panel. Note that is is for a PRE- 1968 model, because it has the mount area for the inside rear view mirror at the top center of the panel. Remember-- the Saab 95/96 cars up to and including 1967 had SHORTER windshields and rear windows....

Here is a closer look at the area where the Monte Carlo instrument mount panel will be fitted. Note the rust and discoloration on the main panel. I had not yet cleaned it up, nor repainted it.

YIKES! A giant HOLE has to be cut to fit the MC panel in place. This has to be done VERY carefully because enough material has to be cut away to clear the instruments, but material must be left for the six mounting studs on the MC panel. I have done this modification before, so I have a pattern that takes the guess work out of the job.

MUCH very careful trimming must be done to get a good fit of the MC panel. The six warning light holders have to fit onto the back of the MC panel, which usually requires MORE very careful trimming. Finally, the edges of the stock Saab instrument panel--at the cut-out area--have to be bent to just fit evenly to the MC panel. That MC panel is made of 50 year old plastic, remember, and does NOT care to bend.

Saab glove box doors have seven main pieces, as shown. I disassembled the door, then sanded, primed and painted the four main parts. It was a lot of screwing around, just to get a good looking glove box door, in the correct color. But there it is....

This photo shows the flip side of the door. The cup holder part is on the left, the not yet installed Monte Carlo 850 panel on the table, in front...

...and here is the glove box door, reassembled, ready to install in the instrument panel. Looks good, eh?

OK...Here is the finished product....Cleaned, straightened, sanded, primed, sanded, primed, sanded, primed, then finally given 3 coats of color. Mighty nice, don't you think?

A closer look at the installed Monte Carlo instrument mount panel, fitted in place, with all the instruments and warning lights.

The final, finishing touch will be a new instrument panel TOP. There are no originals, period. There a VERY few factory replacement top panels around [which were made without the grooves] but good luck finding them. Mark Ashcraft builds an exceptionally nice fiberglass replacement top panel, which comes primed and ready for finish painting and installation. He includes very good How-To instructions.

Tuesday, May 31, 2016

RECONDITIONED V W VANAGON WINDOW LIFT MOTOR

Once in a while you run into something amazingly stupid. Take this BOSCH window lift motor for example. It is out of a 1990 V W Vanagon. This thing is about an inch and a half [more or less] square and about 5 inches long. It looks pretty nasty, and that is after I did some cleaning on it.

This is the flip side. Even nastier on this side. But wait...it gets better...

Well, maybe not actually better...inside, it looked like it had spent a good bit of time at the bottom of Lake Yuk! In fact it took about an hour to convince the brush holder [in my hand] to even come out of the motor body. That brush holder, by the way, has to carry the brushes, the brush holders, the pressure springs, and a set of starter coils. There is so little room in that brush holder that the brushes have to be of STARTER BRUSH material, because they are so short. Carbon brushes would wear out in weeks, apparently... Just try to buy starter brushes these days, particularly TINY little shits that could be used in this sucker!

The armataure is supposed to be shiny and bright....not Lake Yuk black. See, the

V W people, in their infinite wisdom, placed the motor in the door of the Vanagon so rainwater runs right onto--and into--the motor. When I took it apart I got at least three tablespoons full of water out of it. Good stuff, eh? Yeah, results of grand engineering...

Well, I DID finally find some starter brushes that I could cut down and I DID figure out how to install them in this sucker. This is the reconditioned motor--looking better than new and ready to go back into that superbly engineered VW Vanagon door. A door that now has a custom made water deflector over the window lift motor. Great stuff, re-engineering what the engineers should have done right in the first place.

This is the flip side. Even nastier on this side. But wait...it gets better...

Well, maybe not actually better...inside, it looked like it had spent a good bit of time at the bottom of Lake Yuk! In fact it took about an hour to convince the brush holder [in my hand] to even come out of the motor body. That brush holder, by the way, has to carry the brushes, the brush holders, the pressure springs, and a set of starter coils. There is so little room in that brush holder that the brushes have to be of STARTER BRUSH material, because they are so short. Carbon brushes would wear out in weeks, apparently... Just try to buy starter brushes these days, particularly TINY little shits that could be used in this sucker!

The armataure is supposed to be shiny and bright....not Lake Yuk black. See, the

V W people, in their infinite wisdom, placed the motor in the door of the Vanagon so rainwater runs right onto--and into--the motor. When I took it apart I got at least three tablespoons full of water out of it. Good stuff, eh? Yeah, results of grand engineering...

Well, I DID finally find some starter brushes that I could cut down and I DID figure out how to install them in this sucker. This is the reconditioned motor--looking better than new and ready to go back into that superbly engineered VW Vanagon door. A door that now has a custom made water deflector over the window lift motor. Great stuff, re-engineering what the engineers should have done right in the first place.

Thursday, May 5, 2016

SAAB MONTE CARLO INSTRUMENT RECONDITIONING, PLUS

This is the flip side of a Saab Monte Carlo instrument module, in all its beat up glory. Rust, corrosion, hard handling, and 50 years time have taken their toll. AK!

Here is the front of the plastic instrument mounting panel. It was pretty boogered up. You can't see all the cracks and gouges in the panel, in this photo, but they were there.

The panel had six mounting bolts cast into it--this is the back side--and five of them were ripped out. The panel was also warped and was cracked in about a dozen places.

J B Kwikweld to the rescue! A local hardware store was the source for the 4mm x .7mm bolts, as well as the brass pipe I used to provide the centering sleeves for each of the bolts. There were a number of places where I used the JB to straighten the panel by routing out a long groove, laying in the JB, then holding the panel flat as that brand of killer epoxy cured for 24 hours.

The front of the panel had eight or ten places where there were a lot of little side by side cracks. I ground out each tiny crack with a Dremmel tool, then filled it in with auto body filler and sanded it smooth. This sand-fill-sand-fill-sand process went on for a couple of days.... Then it was time to prime-sand-prime for a while, and finally give it three coats of color. Pretty good, huh?

Each of the instruments were reconditioned. Here is the full set, ready to install in the car.

And here are the four major instruments sitting in the repaired and repainted mounting panel. All the warning lights--not shown in this photo--were also reconditioned--they were just as grubby as the rest of the module [see photo one--above]. The owner could have just whacked out a panel out of aluminum and screwed it to the instrument panel of his Saab 96, but chose to have me do the job right...and you can see the results. Reminds me of a sign I saw one time on the shop of an old time welder/blacksmith: "I can mend anything but a broken heart."

Here is the front of the plastic instrument mounting panel. It was pretty boogered up. You can't see all the cracks and gouges in the panel, in this photo, but they were there.

The panel had six mounting bolts cast into it--this is the back side--and five of them were ripped out. The panel was also warped and was cracked in about a dozen places.

J B Kwikweld to the rescue! A local hardware store was the source for the 4mm x .7mm bolts, as well as the brass pipe I used to provide the centering sleeves for each of the bolts. There were a number of places where I used the JB to straighten the panel by routing out a long groove, laying in the JB, then holding the panel flat as that brand of killer epoxy cured for 24 hours.

The front of the panel had eight or ten places where there were a lot of little side by side cracks. I ground out each tiny crack with a Dremmel tool, then filled it in with auto body filler and sanded it smooth. This sand-fill-sand-fill-sand process went on for a couple of days.... Then it was time to prime-sand-prime for a while, and finally give it three coats of color. Pretty good, huh?

Each of the instruments were reconditioned. Here is the full set, ready to install in the car.

And here are the four major instruments sitting in the repaired and repainted mounting panel. All the warning lights--not shown in this photo--were also reconditioned--they were just as grubby as the rest of the module [see photo one--above]. The owner could have just whacked out a panel out of aluminum and screwed it to the instrument panel of his Saab 96, but chose to have me do the job right...and you can see the results. Reminds me of a sign I saw one time on the shop of an old time welder/blacksmith: "I can mend anything but a broken heart."

Thursday, March 3, 2016

SAAB SPEEDOMETER--DUAL REGISTER INTO A STANDARD 2-STROKE

What we have here is a HYBRID speedometer. My customer wanted a dual register speedometer--as in a Monte Carlo--for use in his standard 1966 96 two stroke car. The trouble was that the Monte Carlo cars--either two-stroke or V4--had a transmission with a 4.88:1 final drive transmission. The '66 two-stroke had a transmission with a 5.43:1 final drive. So the MC speedometer would be WAY WRONG in both SPEED and MILEAGE recording......Hmmmmm.....

Clearly, the solution was to change the internal gearing of the MC speedometer [see first photo]. After some head-scratching, I did that gearing change, and the finished speedometer [above] reads correctly on the test bed, for a Saab with 5.43:1 gears.

Here is the flip side of the finished speedometer. I set the odometer miles to match the miles currently shown on the speedometer in the customer's car. The change-over can be done, but it is nice to prove that the change was done correctly, by running the finished speedometer on the test bed. Good stuff!

Clearly, the solution was to change the internal gearing of the MC speedometer [see first photo]. After some head-scratching, I did that gearing change, and the finished speedometer [above] reads correctly on the test bed, for a Saab with 5.43:1 gears.

Here is the flip side of the finished speedometer. I set the odometer miles to match the miles currently shown on the speedometer in the customer's car. The change-over can be done, but it is nice to prove that the change was done correctly, by running the finished speedometer on the test bed. Good stuff!

Wednesday, January 13, 2016

JACK ASHCRAFT'S ARTWORK--PHANTOM DRAWINGS

Every once in a while it is good to "show off", assuming you have something to show. One of my evils is doing "phantom" drawings. You know, those drawings done as though the outer skin is clear plastic. The drawing above was my FIRST phantom, done in the winter of 1962. [Yeah, I know...back when dinosaurs roamed the earth...]

John Callies' FIAT Topolino with a 303 CID Pontiac V8 engine was the first phantom drawing that I got paid for doing. John used the car--and my art work--to promote the various products that he marketed. This was one scary little bomb to drive or ride in!

Another FIAT, this one a 1937 model, my own car, MR T. Mechanicals were almost all FIAT, including the 2-litre twin cam engine, 5 speed trans, disc brakes, etc. It even had some SAAB parts! I built new fiberglass rear fenders, spare tire cover, the hood/front fenders assembly, and some other stuff.

HA! Another one I got paid for. This is a kit car, built by a small company in Oklahoma City, between tornadoes, one assumes. It has a 5-litre Ford V8 engine, disc brakes, a fuel cell, and a ton of other goodies.

Well, of course I did phantom drawings of SAABS! Above, a very special Sonett III with all new fiberglass up front, and a complete re-style of the arse end. Engine is a 1.7 litre V4 Ford of about 120 bhp, and yup, those ARE Ronal wheels.

This is FAST FREDDY, my '68 Sonett V4 autocross and hill climb racer. Freddy's V4 engine produced right at 150 bhp and a winter diet got his weight down to 1490 pounds, ready to race. Competitors hated to see me arrive in Freddy. In 5 years of autocross racing, I can count the number of times I was beaten in my class, on one hand.

Another highly successful race car, believe it or not. My son Chris and I built TITO, an '86 Yugo, for Pacific Northwest autocross racing. The engine was a 1.5 litre FIAT X1/9 engine producing the better part of 140 bhp. This was another car that the competitors hated to see arrive at the race courses.

Here is another drawing done for a kit car manufacturer. It boasted a fiberglass body and square steel "space" frame, and was set up for VW, Porsche or Corvair power. And yup, I got paid for this one, too.

I did this drawing of Ford's Mustang One for an article in a magazine. Note the twin radiators, one on each side of the engine. A pity Saab wouldn't consider producing a roadster...Ford's contract builders, Troutman and Barnes, in Southern California, who produced half a dozen of these cars, had done all the work already. When Ford decided NOT to produce the Mustang One, Saab could have had it for a song.

I got serious about phantom drawings with this one, completed when I was in my final semester of Automotive Design at Art Center College of Design in L.A. in 1975. We seniors were doing a design project for General Motors for a proposed new LaSalle.

Airplanes are fun to draw. This one is a Bradley Aerobat. Bradley Aerospace was a very small company in Chico, California, building these little aluminum buggers as kits. Modified VW engines were the normal powerplant used. I completed a multi-page, step-by-step assembly manual for this little bird.

My pay for doing an assembly manual for the Polliwagen was a complete Polliwagen KIT! This was a side-by-side, two place composite bird that could be ordered with retractable landing gear, fixed, or full flying tail, and could be configured for a VW engine, or larger powerplants up to and including the 150 bhp Lycoming O-320. It was fun to fly and was a genuine 200 mph bird with the larger engine.

All of the original art for these drawings was done about 16" x 24" size, in order to get the level of detail you see. I always use a LOT of photographs to get the details correct, and when possible, go to the factory so I can really see--and photograph-- the "bare bones" of the car or airplane. It is not in my nature to guess at anything.

I hope you have enjoyed my bit of "showing off!"

John Callies' FIAT Topolino with a 303 CID Pontiac V8 engine was the first phantom drawing that I got paid for doing. John used the car--and my art work--to promote the various products that he marketed. This was one scary little bomb to drive or ride in!

Another FIAT, this one a 1937 model, my own car, MR T. Mechanicals were almost all FIAT, including the 2-litre twin cam engine, 5 speed trans, disc brakes, etc. It even had some SAAB parts! I built new fiberglass rear fenders, spare tire cover, the hood/front fenders assembly, and some other stuff.

HA! Another one I got paid for. This is a kit car, built by a small company in Oklahoma City, between tornadoes, one assumes. It has a 5-litre Ford V8 engine, disc brakes, a fuel cell, and a ton of other goodies.

Well, of course I did phantom drawings of SAABS! Above, a very special Sonett III with all new fiberglass up front, and a complete re-style of the arse end. Engine is a 1.7 litre V4 Ford of about 120 bhp, and yup, those ARE Ronal wheels.

This is FAST FREDDY, my '68 Sonett V4 autocross and hill climb racer. Freddy's V4 engine produced right at 150 bhp and a winter diet got his weight down to 1490 pounds, ready to race. Competitors hated to see me arrive in Freddy. In 5 years of autocross racing, I can count the number of times I was beaten in my class, on one hand.

Another highly successful race car, believe it or not. My son Chris and I built TITO, an '86 Yugo, for Pacific Northwest autocross racing. The engine was a 1.5 litre FIAT X1/9 engine producing the better part of 140 bhp. This was another car that the competitors hated to see arrive at the race courses.

Here is another drawing done for a kit car manufacturer. It boasted a fiberglass body and square steel "space" frame, and was set up for VW, Porsche or Corvair power. And yup, I got paid for this one, too.

I did this drawing of Ford's Mustang One for an article in a magazine. Note the twin radiators, one on each side of the engine. A pity Saab wouldn't consider producing a roadster...Ford's contract builders, Troutman and Barnes, in Southern California, who produced half a dozen of these cars, had done all the work already. When Ford decided NOT to produce the Mustang One, Saab could have had it for a song.

I got serious about phantom drawings with this one, completed when I was in my final semester of Automotive Design at Art Center College of Design in L.A. in 1975. We seniors were doing a design project for General Motors for a proposed new LaSalle.

Airplanes are fun to draw. This one is a Bradley Aerobat. Bradley Aerospace was a very small company in Chico, California, building these little aluminum buggers as kits. Modified VW engines were the normal powerplant used. I completed a multi-page, step-by-step assembly manual for this little bird.

My pay for doing an assembly manual for the Polliwagen was a complete Polliwagen KIT! This was a side-by-side, two place composite bird that could be ordered with retractable landing gear, fixed, or full flying tail, and could be configured for a VW engine, or larger powerplants up to and including the 150 bhp Lycoming O-320. It was fun to fly and was a genuine 200 mph bird with the larger engine.

All of the original art for these drawings was done about 16" x 24" size, in order to get the level of detail you see. I always use a LOT of photographs to get the details correct, and when possible, go to the factory so I can really see--and photograph-- the "bare bones" of the car or airplane. It is not in my nature to guess at anything.

I hope you have enjoyed my bit of "showing off!"

Labels:

Aircraft Art,

Automotive Art,

Phantom Drawings,

Saab Artwork

SAAB 95/96/97 BACK UP LIGHT SWITCHES

These are the [made of unobtainium] back up light switches for Saab 95/96/97 cars that I recondition. The drawing above shows where the switch is located on the Saab transaxle, and the internals of the switch. Nothing much to them...right? Well, yes and no. Because of the nasty environment where they "live", they get really grubby and corroded inside. The trick is to get them apart without destroying them. AH! as the Bard of Avon said, "There's the rub!"

Here are 16 switches. At the bottom, one switch disassembled. Above, are 15 switches that I have reconditioned and tested. As I said, getting them apart without destroying the switch is the trick, and it is a bitch....unless...

...you happen to have my special tools. Top center--the tool that holds the switch so you can use the bottom tool to UN-crimp the steel body of the switch WITHOUT breaking the plastic switch body. The same tool is used to RE-crimp the steel body of the switch. The little red tool is a special holder for trimming tiny brass screws that I sometimes have to use to hold a new connector when one of the electrical connector tabs are broken off.

If you are wondering where to get these tools....they're made of unobtainium, too. Just send me you dead switch and I'll recondition it. When I'm done with it, it will look like one of the 15 switches in the center photo. Good stuff, huh?

Here are 16 switches. At the bottom, one switch disassembled. Above, are 15 switches that I have reconditioned and tested. As I said, getting them apart without destroying the switch is the trick, and it is a bitch....unless...

...you happen to have my special tools. Top center--the tool that holds the switch so you can use the bottom tool to UN-crimp the steel body of the switch WITHOUT breaking the plastic switch body. The same tool is used to RE-crimp the steel body of the switch. The little red tool is a special holder for trimming tiny brass screws that I sometimes have to use to hold a new connector when one of the electrical connector tabs are broken off.

If you are wondering where to get these tools....they're made of unobtainium, too. Just send me you dead switch and I'll recondition it. When I'm done with it, it will look like one of the 15 switches in the center photo. Good stuff, huh?

Subscribe to:

Comments (Atom)