This photo shows a wide variety of Bosch distributors and distributor parts--ALL of which were supplied to Saab for their V4 engines. There were at least a dozen DIFFERENT Bosch distributors used on the Saab V4 engine, and while some parts are interchangeable, many are NOT. On the left is a really nasty Bosch/V4 distributor--typical of the way they look when I receive them. Moving to the right, there are 7 different drive gears. To the right of that the MAIN distributor parts---body, main shaft, top shaft. Then, a vacuum control unit [one of a dozen different ones used], a points plate [one of four used], a condensor [one of 10 different ones used], a set of points [one of two used], and a rotor [one of 6 used].The box holds half a dozen different top shafts, then several different movable points plates, and one of two different distributor caps. Finally, there are three different distributor assemblies and two different vacuum control units. I've reconditioned close to 500 Bosch distributors, and I still--occasionally--run onto something I have not seen before!

Here are two Bosch V4 distributors with MAJOR differences. The top unit is what I call a "notch body" distributor. Note the extended casting on the side, near the top of the distributor body. This requires a vacuum control unit with its mount configured for that notch body. The distributor body below it is a "round body" type. Note that the vacuum control unit is assembled with a round mount.

Inside, the fun is just beginning. On the left is a very early internal shaft assembly, on the right one of the later shaft assemblies. Because of the orientation of the rotor notch in the top part relative to the 4 lobes that open the points, these will NOT interchange. To further the fun, the later assembly [on the right] has four different lobe-to-notch arrangements and they will NOT interchange, either. In reconditioning these distributors, it is essential to know what parts are compatible. If you don't, you will probably get the thing all back together again and it simply will not work. Fun stuff, eh?

This shows the parts of the internal shafts. On the left, starting at the top, the lower shaft. On either side are the two mechanical advance weights, with their control springs just below them. At the bottom, the top shaft, with the four lobes that open the points, and the notch for the rotor. On the right, the assembled shaft. I control--and can tailor--the mechanical advance curve of the distributor, by changing the advance SPRINGS. I plot the actual curve by running the distributor on the SUN distributor machine, noting the degrees of advance at various readings through the useable RPM range. Sometimes a lot of springs get changed before I'm satisfied with the curve.

Virtually ALL the distributors I receive must have a bushing installed at the bottom of the distributor body. I use a special tool to hold the distributor body so I can drill it in the lathe for the brass bushing. In this picture the bushing has been installed and this setup is for reaming the bushing to the correct inside diameter. This is a fairly delicate process, to get JUST the right I.D. for the shaft, plus just the right clearance. Well....after bushing close to 500 distributors, I DO have that process figured out.

What makes YOUR V4 distributor a candidate for reconditioning? Uneven idle, poor performance, excess fuel consumption, hard starting are a few symptoms. Remember---these gesparkers are 40+ years old! Many Saab V4 owners are amazed at how much better their 40+ year old Saab runs with just a properly reconditioned distributor installed. How's yours running?

Wednesday, December 26, 2012

Saturday, December 22, 2012

SAAB V4 ENGINE--REALLY SCREWED UP!

You are looking at a very screwed up Saab/Ford V4 engine block. I took this one apart to do a complete overhaul. The piston in the photo IS at top dead center. I rigged the dial indicator to measure how far the crown of the piston is below "deck height" [top surface of the block]. The drill is to get a starting point, so I set the dial indicator at some number greater than the estimated depth of the piston below deck height. I also know the thickness of the steel strap.

Next is to remove the strap and take a measurent at the piston crown. I subtract this measurement [plus the amount of the strap thickness] from the first reading. The result was 0.247". This is a 1698cc V4. We all know [don't we?] that the pistons in the stock 1698cc V4 do not come up to deck height BUT they certainly are not a quarter inch below it! ZOUNDS! Some metally challenged mechanic really did a number on this little engine.

But wait! There's more! It's hard to see in this photo but the cylinder walls are a mess. There is about six jillion tiny hammer marks, all evenly spaced in that shiny area above the piston. What the hell caused that? I am not sure. Perhaps a worn out boring bar [the engine was bored .5mm (0.020") oversize] or an equally worn out hone of some sort. So what does this have to do with the deck height problem? Well, sports fans, when I got the sucker all apart I find that the super smart "wrench" who did this work managed to fit [new] pistons for a 1698cc engine onto a 1498cc crankshaft, resulting in the 0.247" under deck height measurement.

This same genius had the crankshaft turned 0.010" undersize on the main bearing journals, and 0.020" undersize on the connecting rod journals, BUT then installed bearings that were ALL 0.010" oversize. That sucker must have rattled quite a lot had had about as much power as an old two stroke Saab with one plug wire pulled off!

Proving once again that these little V4's are pretty special and require some special knowedge--like factory manuals and 40+ years of Saab experience-- in order to rebuild them correctly. A hack mechanic who once overhauled a Chevy pickup engine has absolutely no business getting within a city block of a Saab V4. This particular rocket scientist managed to make the Saab owner pay TWICE to get his engine overhauled correctly.

Wednesday, December 5, 2012

VDO CLOCK--MYSTERY

I need some help here, gang. I received this clock yesterday--for reconditioning--and I have NO IDEA what vehicle it came out of. The owner provided no phone number or email address. Do YOU recognize the critter?The outside diameter of the outer ring is 3.744" and the outer ring is brass color.

The clock has two mount tabs, as you can see, and the auto-rewind section is the common VDO-Kienzle unit. Build date stamped on the auto-rewind section is 5-73.

Side view of the Mystery Clock. It is a VDO unit so that means it probably came from a European vehicle circa 1973. If you know what it might have come from, please let me know. Jack Ashcraft--phone 541-499-0246 or email me at jacksonashcraft@gmail.com

The clock has two mount tabs, as you can see, and the auto-rewind section is the common VDO-Kienzle unit. Build date stamped on the auto-rewind section is 5-73.

Side view of the Mystery Clock. It is a VDO unit so that means it probably came from a European vehicle circa 1973. If you know what it might have come from, please let me know. Jack Ashcraft--phone 541-499-0246 or email me at jacksonashcraft@gmail.com

Sunday, December 2, 2012

BMW MOTORCYCLE IGNITION & LIGHTING SWITCH PLATE

Holy switchplates, Batman! This is a clear cut case of the good, the bad and the ugly! These are igntion & lighting switch plates from a 72 Bimmer Bike. On the left, the charred remains of the original. On the right, a new switch plate--possibly the only new one in captivity--which set the Bimmer owner back something on the order of $175.00! Yikes!

View of the BOTTOM of the two plates. Obviously, there is work to be done on Old Nasty [left] which is dead as a door nail here.

Top view of the two plates. Old Nasty [left] hung in there for 40 years so I reckon the owner can't whine too much about it giving up on him. But it's time to lop off the cremated wires and give the sucker the sheep dip [clock cleaner and rinse] treatment!

HA! There IS life after death! New wires and ready to go for another 40 years! I recondition a TON of switches--for cars and bikes--as well as making auto clocks and cable driven speedometers and tachometers work like new. MOST old dead ones can be revived--good stuff, Mate!

View of the BOTTOM of the two plates. Obviously, there is work to be done on Old Nasty [left] which is dead as a door nail here.

Top view of the two plates. Old Nasty [left] hung in there for 40 years so I reckon the owner can't whine too much about it giving up on him. But it's time to lop off the cremated wires and give the sucker the sheep dip [clock cleaner and rinse] treatment!

HA! There IS life after death! New wires and ready to go for another 40 years! I recondition a TON of switches--for cars and bikes--as well as making auto clocks and cable driven speedometers and tachometers work like new. MOST old dead ones can be revived--good stuff, Mate!

Saturday, November 17, 2012

BMW MOTORCYCLE--MOTOMETER SPEEDOMETER/TACHOMETER

Something a bit different.....this is a Motometer speedometer/tachometer from a '72 BMW motorcycle. The Motometer weenies managed to stuff a cable driven speedo AND a cable driven tach into one case. Turns out that the main input shaft housing for both the speedo and the tach are essentially the same, except for different size threads for the drive cables. The item just behind the tach face is the input SHAFT. Just behind it is the input HOUSING.

This shows the vertical shaft assembly--the gubbins that operates the odometer in the speedo section--which is omitted for the tach. Typical of such 40 year old instruments, the grease was hard as a brick bat. As always, I took the sucker completely apart, cleaned, lubed and adjusted it, and for the speedometer section, calibrated it for speed vs miles.

The whole schmere...well, the major players, anyhow...are shown here. The small cylinders just behind the speedometer assembly are the tubes for four warning lights. Everything in this photo has been reconditioned. All that was left was zinging it back together. Interesting little instrument! Don't be hesitant to contact me if you have a cable driven speedo or tach that needs help---I'll take a look at it and see if I can give it some new life!

This shows the vertical shaft assembly--the gubbins that operates the odometer in the speedo section--which is omitted for the tach. Typical of such 40 year old instruments, the grease was hard as a brick bat. As always, I took the sucker completely apart, cleaned, lubed and adjusted it, and for the speedometer section, calibrated it for speed vs miles.

The whole schmere...well, the major players, anyhow...are shown here. The small cylinders just behind the speedometer assembly are the tubes for four warning lights. Everything in this photo has been reconditioned. All that was left was zinging it back together. Interesting little instrument! Don't be hesitant to contact me if you have a cable driven speedo or tach that needs help---I'll take a look at it and see if I can give it some new life!

Saturday, November 3, 2012

SAAB V4 TRANSMISSION DIP STICK

SAAB, in their infinite wisdom, made the transmission for the 95/96/97 models VERY unhandy when it came to checking the transmission oil level. The drill is to remove the check plug [see drawing above] and if oil runs out, the oil level is good. If no oil runs out, take out the fill plug and add oil until it does run out, then replace the check plug. Some Saab owners don't even know where the check plug IS, and has even less inclination to go through this drill. So a dip stick is a real good idea, and can prove to be a transmission saver since the owner MIGHT actually check the transmission oil level on occasion.

I built a construction fixture [red item at the bottom in the photo above and top red item in the photo below] that exactly matched an original SAAB trans dip stick, so when the stock of dip sticks have been sold, I whip out the fixture, and make up some more of them.

I built a construction fixture [red item at the bottom in the photo above and top red item in the photo below] that exactly matched an original SAAB trans dip stick, so when the stock of dip sticks have been sold, I whip out the fixture, and make up some more of them.

This photo shows seven [of a dozen] freshly completed dip sticks plus the original Saab dip stick [red, top next to the fixture]. I add the "MIN" and "MAX" notches, as per the original. Now, y'see, all you have to do is remove the fill plug with a 3/8" drive extension, dip the dip stick into the trans, pull it out, read the oil level, add if necessary, put the fill plug back into the transmission case, wipe off the dip stick, and if you're a neatnick, you didn't even get oil on your hands. PLUS, your transmission stays properly oiled and happy. By the way--SAAB used to offer these dip sticks through their dealers. Since that is no longer an option to the vintage Saab owner, I thought it would be a good idea if I made the little buggers available. Good stuff, huh?

Thursday, October 25, 2012

Volkswagen Signal Switch Mystery Solved

This is a 1958 thru 62 Volkswagen direction signal switch--taken apart. These are notable because the switch itself allows both the direction signals and the brake lights to work with just one bulb on each side at the rear. Not this switch though---it worked only part of the time for turning left and not at all turning right.

I asked several VW techs how this type of switch worked. Summed up, their answer was, "...uhh...it's all in that switch." I already knew that so I took one apart to find out. Above [left]--the corroded contact plate. On the right-- the greasy mechanical gubbins. This one was NASTY inside!

The same grubby contact plate on the left. On the right--an interesting rotating contact plate that makes the one-bulb system work correctly.

The parts look a lot better after going through the sheep dip in the ultrasound tank. I gave the parts a special rinse in the ultrasound tank and careful lubrication with modern, non-hardening lubes. Nothing was broken in this switch--but it was a mess of old, very hard grease and a lot of corrosion.

All better now and ready for another 50 years of service in somebody's restored Beetle!

I asked several VW techs how this type of switch worked. Summed up, their answer was, "...uhh...it's all in that switch." I already knew that so I took one apart to find out. Above [left]--the corroded contact plate. On the right-- the greasy mechanical gubbins. This one was NASTY inside!

The same grubby contact plate on the left. On the right--an interesting rotating contact plate that makes the one-bulb system work correctly.

The parts look a lot better after going through the sheep dip in the ultrasound tank. I gave the parts a special rinse in the ultrasound tank and careful lubrication with modern, non-hardening lubes. Nothing was broken in this switch--but it was a mess of old, very hard grease and a lot of corrosion.

All better now and ready for another 50 years of service in somebody's restored Beetle!

Thursday, September 27, 2012

SONETT II & SONETT V4 REPLACEMENT IGITION SWITCH

Ignition switches get tired after being twisted for over 40 years. Sonett II and Sonett V4 cars at least have an ignition switch you can replace without dismantling the steering column assembly, which is the case with a Saab 95 or 96. The problem with all these cars is that Saab saw fit to run four or five circuits with current that had to pass through the ignition switch. NOT one of their better ideas.

Finding a replacement switch that will mount through the plywood instrument panel was tough enough. Finding one that looked "original"--with keys that say "SAAB"--just wasn't gonna happen--so I figured--just get over it. My solution is shown. The 40 amp relay [extreme left in the photo] keeps the electrical circuit load off the switch and the whole assembly just plugs into the wires that were originally connected to the ignition switch. I matched the new wire COLORS to the old wires and also marked each wire with bands. One hole has to be drilled to mount the relay [I know that's a toughie], but the rest is pretty much "plug and play". As a last resort sort of thing, I put together illustrated step by step instructions. See--I hate to recreate the wheel every time I do something.

SAAB LIGHTS IN AN ITALIAN CAR ???

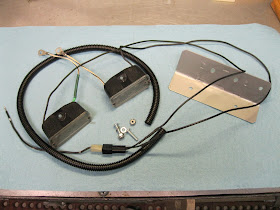

This conglomeration of wires and "stuff" will be one of several interior lights in MR T, my 1937 FIAT Topolino "EuroRod". If you guessed that the two lights were Saab 99 interior lights mounted behind the inside rear view mirror---you're right! The piece of steel angle [on the right, above] will mount the lights just under the rear window on MR T, to light the luggage area behind the seats.

Here is the assembly, ready to install. I'm in the process of doing a complete, NEW wiring job of the entire car, using a LOT of plug-together connectors like the one at the extreme left of the photo above. All good stuff....for someone who actually LIKES to do automotive wiring!

Here is the assembly, ready to install. I'm in the process of doing a complete, NEW wiring job of the entire car, using a LOT of plug-together connectors like the one at the extreme left of the photo above. All good stuff....for someone who actually LIKES to do automotive wiring!

ITALIAN CLOCKS IN A SAAB ???

Here are the gubbins of a couple of ALL ELECTRIC clocks from a couple of Saab 96's. The dial indicator gives you an idea of the size of all that stuff that makes up tickerator. [Good word, eh?]

These all-electric Italian VEGLIA clocks do NOT have the auto-rewind package used in a lot of the VDO tickerators. Instead they have a coil [see photo below] that starts the rocking action of a small weighted wheel that puts the gearset into motion, causing the hands to move.

The small "spoon" [just above the coil] is an electrical connector. As with ALL clocks, these little suckers have to be carefully cleaned, rinsed and then lubed with professional "right stuff", or there's no point in trying to recondition the clock in the first place. I also "hot check" 'em for an hour, to check for time accuracy and to give them a fresh run-in period after they've been messed with.

Here is a reconditioned tickerator. There are four parts missing: a chrome "cup" that fits over the set shaft next to the glass, a wee spring, a chrome set knob, and the setscrew that holds the knob in place. They were not on the clock when I received it from the customer. I hope he held on to them because they are made of "unobtainium."

These all-electric Italian VEGLIA clocks do NOT have the auto-rewind package used in a lot of the VDO tickerators. Instead they have a coil [see photo below] that starts the rocking action of a small weighted wheel that puts the gearset into motion, causing the hands to move.

The small "spoon" [just above the coil] is an electrical connector. As with ALL clocks, these little suckers have to be carefully cleaned, rinsed and then lubed with professional "right stuff", or there's no point in trying to recondition the clock in the first place. I also "hot check" 'em for an hour, to check for time accuracy and to give them a fresh run-in period after they've been messed with.

Here is a reconditioned tickerator. There are four parts missing: a chrome "cup" that fits over the set shaft next to the glass, a wee spring, a chrome set knob, and the setscrew that holds the knob in place. They were not on the clock when I received it from the customer. I hope he held on to them because they are made of "unobtainium."

Thursday, August 30, 2012

TOPOLINO HEADLIGHTS & WIRING

Say hello to "MR T..." I got tired of looking at empty light sockets and wired up the VW Beetle headlamp assemblies to go into the wee car. I had already installed the signal lamps in the small grille openings on each side.

Here's the wired up light set. Beetles had the park lamps inside the glass in these headlight units. Works OK for me---Hey! It's a 1937 car!

Here's the wired up light set. Beetles had the park lamps inside the glass in these headlight units. Works OK for me---Hey! It's a 1937 car!

Even boids flyin' over think MR T looks better with his eyeballs installed!

SAAB 95/96 IGNITION KEY/SWITCH/RELAY SYSTEM

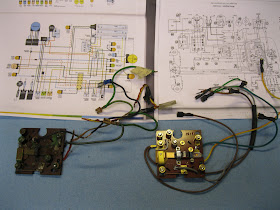

This conglomeration of wires and stuff is [left to right] 1--the steering column housing from a Saab 95/96. You are looking at it from a view you will never see when it is mounted inside the car. The steering wheel would be just beyond the TOP of the black housing. The round shiny thingy at the right center is a new, heavy-duty replacement ignition switch. It is part of one of my new ignition key/relay systems for these cars. The relay is under the switch on the outside of the column housing. The wire bundle is routed to plug right back into the original wires that were formerly attached to the stock ignition switch.

2--Center is the assembly jig showing the same switch, relay and wiring bundle.

3--At right is a completed system, ready to go in the box for shipment to a Saab customer who really would like to just get into his car, shove in the key, turn it, start the engine and be about his business.

These are the same items, viewed from the front. Note that the ignition key is now on the LEFT side of the column housing. SOME 95/96 cars had the 4-way flasher switch on the left. It is now on the RIGHT, for those cars. MOST 95/96's had the 4-way switch up on the panel to the left of the instruments, AND For those cars, there is a black, push-in plug that covers the ignition key hole on the right. It's a neat, bullet-proof system!

Wednesday, August 15, 2012

SAAB Sonett III New Ignition Switch System--Testing

Old--uhh--VINTAGE--cars tend to wear out. Or break stuff. On vintage Saabs the ignition keys/cylinders/locks get tired and finally head West. New Saab parts are NOT available, so I engineer good quality replacements that work well and are reliable. In the case of the Sonett III cars, you have it easy. All you have to do is get rid of the housing that carries the key cylinder AND the steering column lock mechanism. It is a pain in the butt anyhow. Saab 96 & 96 cars are even worse, but I'll talk about them later.

Saab used snap off bolts to hold the mechanism to the Sonett III steering column. I use a very sharp small chisel and ball peen hammer and back those bolts out. It is easier than you think [see drawing above]. I have a very good replacement system for the Sonett III cars, which bolts quickly back into place, right where the original assembly sat.

I refuse to install anything I don't test first. Above is the simple test rig I use to make sure I have the replacement ignition switch system wired correctly. The bulbs light up as I turn the new switch to it's "ON" and "START" positions.

The switch is in the "ON" position here. Current is flowing through the heavy wire that will feed 5 fused circuits in the Sonett, as well as to the coil circuit for running the engine. I got that one wired correctly--HA!

This is the prototype replacement switch/relay/wiring/mount assembly for a Sonett III. It would be rotated 180 degrees to mount in an actual car. Once in place, all you have to do is pull the wires off the old ignition switch--one at a time--and plug 'em into the [well marked] wires shown here, and you are good to go. Pretty neat, eh?

Wednesday, August 8, 2012

Engine Cooling Fan Fix

Everyone needs to work on his/her Subaru Brat once in a while....assuming he/she owns a Subaru Brat. This is "MR B", my wee Subie 2 or 4 WD pickup. Neat little truck!

These are the parts---fan blade, motor ass'y and mounting shroud.

The sealed motor is NOT meant to be taken apart. So, of course, I took it apart. The shaft bushings--after only 182,000 miles--were dry. I cleaned up the armature, the shaft, the bushings and the four wee brushes, lubed the bushings and put it back together again. Works like a champ.

The assembly, ready to go back into MR B. Good to go for another 182,000 miles. See how much fun it is to work on your Subaru!

Sunday, July 15, 2012

TOPOLINO HEATER/DEFROSTER CONTROL BOX

MR T, my 1937 Fiat Topolino EuroRod, got a bit more attention during the last week. Above is the custom heater/defroster control panel that I built. The car is very small so I've attempted to make every part in the car do two or more jobs. This panel is no exception. The knob on the left controls heater fan speeds, the slides just to the right

control heat, vent and defrost on the heater "box" itself. The center orange lamp indicates when the secondary direction signal semaphores pop out and flash. The red lamp just below lights up when the emergency brake is "on". The two slides on the right control the outer air inlet door on the side of the cowl ahead of the right door, and the 3 position switch on the right controls the semaphore flashers on each side of the car.

This shows the INSIDE of the panel and all the gubbins that go into, or onto, it. The flasher units [top right] are for 1] the regular direction signals, and 2] the semaphore flashers. The latter are just for fun, but they were standard equipment in 1937.

This is the inside with all the bits mounted up. Two relays are mounted outside the box [extreme left side].The unit under the box on the left is the intermittent windshield wiper switch [a standard item on '70's-'80's Fiats], and the two flasher units are under the box on the right. It will get a lot more interesting when all the wires are added, plus the five operating cables. Like I said, I like to make one item do a lot of jobs, and this is typical of the whole car.

For some reason the front surface looks grainy in this photo. It isn't--it's smooth. The box is 10.5" wide and 2.75" high. My wife says I'm having WAY too much fun with this little car. I just look at her and grin and say, "Yeah--ain't it great?"